Advanced Siemens PLC & Touch screen Control system

Pneumatic cut & grab film unit to realize automatic wrapping cycle, labor saving

Easy to set parameters via touch screen

Photo-eye on the turntable conveyor inspect pallet travel in and travel out

Machine automatic start when the pallet travel to the turntable conveyor

Over-wrap provide more wrap over the top of loads

Counter to record pallets Qty be wrapped

Automatic load height detection by photo-eye

Powered pre-stretch film carriage up to 300% (1:3)

CycLe pause capacity

Film tension, Turntable speed, Carriage speed separate adjustment from the control panel

EAT300PPS-RCT inline pallet wrapper has a powered roller conveyor turntable system.

The pallets will be transported to the wrapper and stopped at the wrapping position by the PE, then wrapper start to pack the loads automatically.

The film cutting & wipe system provides a fully automatic wrapping cycle and adherence of the film to the load. Then the wrapped loads will be transported to the outfeed conveyor and waiting for the forktruck unload.

Eopac's Inline Pallet Wrapping Machine Advantage:

1. Siemens advanced PLC controller & 7'' colorful touch screen allows easy to operate.

2. Automatic cut & welding film unit, welding (seal) the film tail automatically to ensure no film tail comes out.

3. Heavy duty design and famous brand parts ensure long life and minimum maintenance.

4. World-famous parts ensure high quality of the whole line.

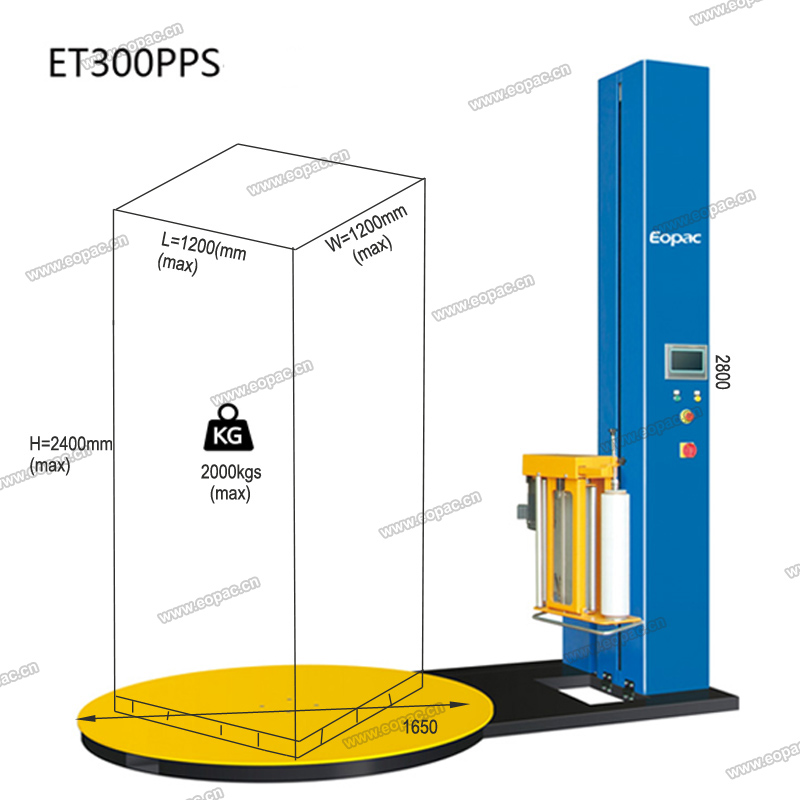

Size of The Loads ( Pallets) to be Wrapped | |

Min load size | 800mm (L) X 600mm (W) |

Max load size | 1200mm (L) X 1200mm (W) |

Max load height | 1800mm (Option:2400,2800mm, 3000mm) |

Max load weight | 2000kg (Option: 3000kgs) |

Machine Performance | |

Packing efficiency | 20-40 loads/hour (Depending on pallet height) |

Load height sensing by PE | YES |

Turntable soft start & stop | YES |

Turntable rotation speed: | 3-15 rpm adjustable |

Turntable diameter | 1800mm (Option: 2000mm,2200mm, 2400mm) |

Turntable height | 450mm (standard) ( Other height available) |

Turntable drive | Slew bearing drive (More reliable and easy to maintenance) |

Turntable conveyor | Drive Roller |

Carriage Up/down Speed | Adjustable |

Film Delivery System | |

Carriage | l Power pre-stretch Film Delivery System, stretch ratio up to 250%. l Film tension adjustable |

Film Clamp & Cut Unit | |

Cutter: | Yes (Hot wire cutter) |

Film tail wipe unit: | Yes ( Pneumatic control) Welding (seal) the film tail, ensure no film tail comes out |

Film tail clamp unit: | Yes ( Pneumatic control) |

Electrical Features | |

Power supply voltage | 380 V 3Phase – 50/60 Hz |

Power | 2.7Kw Turntable motor: 1.1kw Film carriage lift motor: 0.37kw Film feed motor:0.37kw Conveyor motor: 0.75kw |

Machine Weight & Size | |

Machine size (LXWXH) | 3025mm X2000mm X2760mm |

Machine weight | N.W. 1000KG G.W.1100KG |

Options available to custom build to meet specific needs

1.CHAIN TURNTABLE CONVEYOR

For pallets which has small legs or pallet bottom slats is parallel with the movement directions.

2.MOTORISED TOP PLATEN

Add mortorised top platen to protect the unstable products during stretch wrapping

3.TOP SHEET COVER

Independent structure device for covering the top of the pallet for protection against dust. It can be easily installed on existing wrapping lines.

Eopac Machinery also design and make the conveyor system, pallet top Sheet Dispenser, turntable,Pallet Lifter etc to complete the whole line.

Looking for the suitable end-of-line solution?

Contact us soon.

Our experienced technicians will design the end- of -solutions based on your applications.